One of the industries that took a long look at its processes after pandemic-induced shortages was the pharmaceutical supply chain. Unlike some products where disruptions pose only an inconvenience, when the pharmaceutical supply chain is interrupted, for many patients it could be a matter of life and death.

In some ways, the pharmaceutical industry is still suffering effects from the shortages that began during the pandemic. Here are some of the issues the industry is facing, and the role analytics can play in making sure the pharmaceutical supply chain is operating at its highest level.

Types of shortages

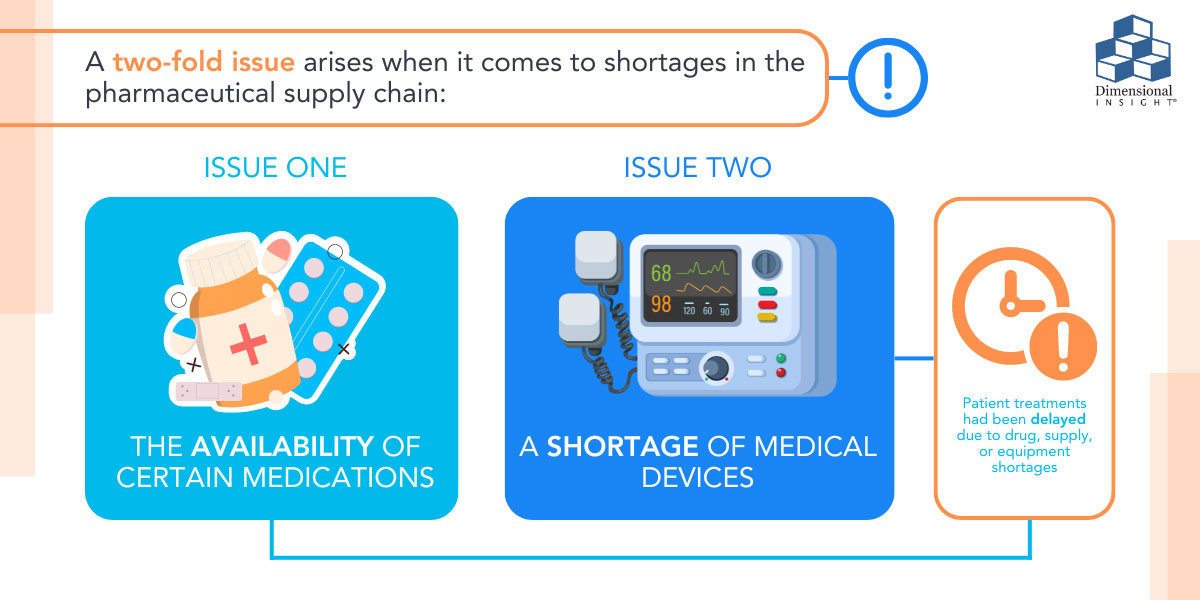

There is a two-fold issue when it comes to shortages in the pharmaceutical supply chain. One is the availability of certain medications themselves. Another, though, is a shortage of medical devices. In a 2023 survey by the patient safety nonprofit ECRI and the Institute for Safe Medicine Practices (ISMP), half of the respondents reported that patient treatments had been delayed due to drug, supply, or equipment shortages. This included interrupted chemotherapy regimens, shortages of products like endotracheal tubes, and needing to postpone or cancel surgeries due to a lack of supplies.

The vast majority of respondents said they regularly inform medical staff about products in short supply. In an effort to not interrupt treatment, there are other risky steps being taken. 42% of respondents said they used drugs, supplies, or equipment that was in short supply beyond its labeling to help get more usage out of it, and 35% said they have purchased an alternative product in short supply from a secondary gray market. While this one survey is not an indication of what is happening everywhere, it does offer evidence that when there are shortages, the quality of care suffers.

Potential solutions

There have been efforts by both public and private entities to address the shortages. Congress has called for the creation of a stockpile program for generic drugs at risk of shortages, and domestic pharmaceutical companies are working to produce drugs that are on the FDA’s shortage list.

Experts point to risk assessment early on as a way to avoid disruptions. When it comes to medical devices and medications, there are certain standards that must be met, and finding qualified suppliers can take time. If potential new suppliers are vetted ahead of time, it can significantly speed up the process.

The role of analytics

In its proposed budget for the 2025 fiscal year, the FDA has dedicated more than $12 million to address supply chain issues, with some of it dedicated to data. The FDA “will advance its capabilities to help prepare for, build resilience to, and respond to shortages through improved analytics and regulatory approaches,” the agency said in a budget summary. The money will be used in efforts to investigate supply chain disruptions and medical product shortages, and “to promote manufacturing quality across the pharmaceutical industry and develop and implement modernized systems to respond to shortages faster.”

The Drug Supply Chain Security Act calls for all prescription drug supply chain trading partners, from manufacturers to distributors and dispensers, to electronically exchange end-to-end drug traceability.

There are analytics solutions that can trace products, and there are others that can map supply chains and provide background information about suppliers. Still more can bring together data on shipments to give a facility an idea of when their medical supplies will arrive. The pharmaceutical industry can be complicated in that data about medical supplies and data about medications could be housed in different places.

The best analytics solutions are the ones that can bring all of that information together to produce comprehensive reports. Organizations can then make informed decisions about next steps, whether it is because they are facing a shortage of some kind, or because the data shows them there could be a problem in the future. When hospitals don’t have the equipment they need, they make decisions out of necessity, and as the ECRI/ISMP survey results show, sometimes those decisions result in situations where quality is not at the level it should be. When reliable analytics are brought in early in the process, decisions could be made that can save lives without sacrificing quality.

- 3 Important Characteristics of a Cannabis Analytics Solution - May 1, 2024

- Analyzing the Challenges of Pharmaceutical Supply Shortages - April 26, 2024

- Summer is an Opportunity for Digital Transformation in Education - April 17, 2024