When President Biden signed a $1 trillion infrastructure bill into law on November 15, a number of industries stood to benefit. Organizations that rely on America’s role in the supply chain were chief among them.

With billions of dollars already aimed at American ports, the hope is that some of the bad news that has dogged the supply chain for months will turn to some good news. Here are some of the issues the supply chain has been facing and how the infrastructure bill could help.

Issues exposed

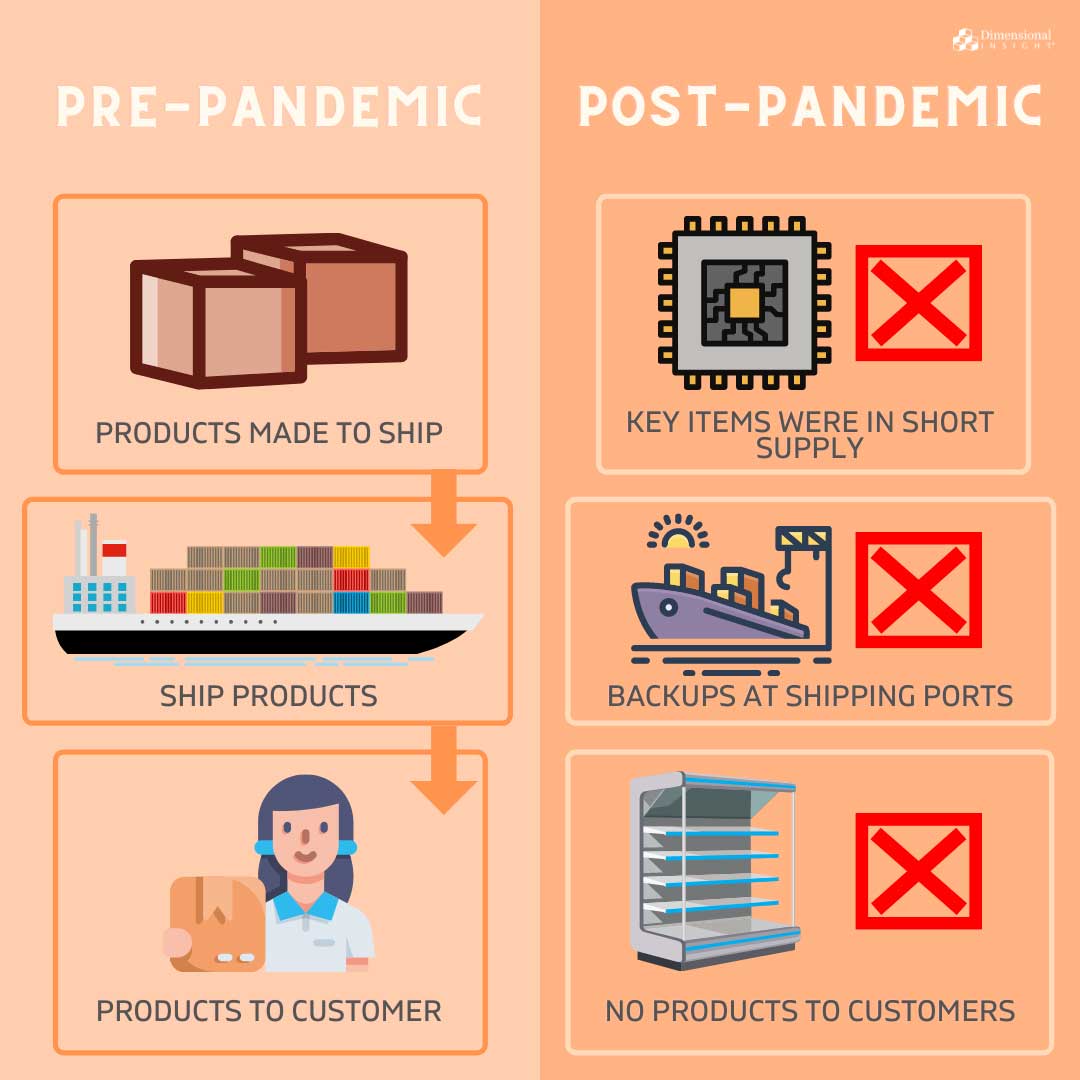

When each link of the supply chain is intact, everything moves along efficiently. Products are made and shipped because all of the necessary components for those products get where they need to be, and all of the moving pieces to get the product to the consumer are in place. Often this has been done on a “just in time” basis, where everything gets where it needs to be in a way where goods are never stored for too long. The pandemic, though, caused a major disruption.

When factories were forced to close down, workers’ schedules were changed to accommodate social distancing, and some workers chose not to return to work facing similar conditions they faced pre-pandemic. That meant products weren’t where they needed to be when they were needed. Computer chips that were needed to complete the production of certain appliances and vehicles were in short supply. Backups formed at ports because there weren’t enough people to unload goods, or there weren’t enough trucks to transport goods away from the ports. While much of the focus has been on bare shelves in grocery stores due to problems importing goods, American businesses trying to export goods have also faced issues. Shipping companies would rather get their containers back to Asia to be loaded with inventory at a higher price than waiting to be loaded again in America with goods that won’t get them as much money.

What billions of dollars can do

The infrastructure bill has already earmarked funds to help ease these issues. The most immediate impact is in funding for pop-up yards that will provide more space for containers being unloaded in Savannah, Georgia, one of the nation’s busiest ports. That storage will allow ships to move in and out of the port more quickly, and hopefully also get products to consumers rather than sitting around the port.

Another aspect of the bill that will help, though it remains to see how long it takes to see the benefit, is in funding to improve railways, roads, and waterways. The places that clog up the movement of goods once they are in the country should see improvements that will ease the strain on domestic shipping. Similarly, the bill lowers to 18 the age of truckers who can cross state lines. This will allow more efficiency in domestic shipping, and the hope is that it will also attract more workers to the job. Trucking as an industry is facing worker shortages due to an aging workforce as well as workers seeking more desirable conditions.

How data can help

In all of these instances, companies have used data to figure out how to run in the most efficient manner. That’s where the “just in time” model developed. Rather than spend money on a warehouse, companies could ship goods directly to where they needed to go when they were needed. But the recent developments have made that untenable, and experts predict that’s not going to change any time soon – even with the implementation of the infrastructure bill.

Organizations can still figure out the most efficient approach to the supply chain using data – they just need to adjust the data they are looking at. The cost of shipping containers is going up, so more of an emphasis might need to be placed on domestic production than what used to be cheaper overseas.

It’s the same approach the American government is taking. Although some of the greening initiatives in the new bill had to be cut back in negotiations, there is still an increased emphasis on a shift to lower-emission cars and trucks. In the future, the Biden administration would also like to see more domestic production of the computer chips that the auto industry relies on that are currently produced overseas. The time to rethink how your organization uses the supply chain is now. The data can help guide you to make the right decisions.

- Analyzing the Challenges of Pharmaceutical Supply Shortages - April 26, 2024

- Summer is an Opportunity for Digital Transformation in Education - April 17, 2024

- Your Car is Tracking More than Miles per Hour - April 11, 2024