A retailer’s goal is to sell what it has in stock. It may sound simple, but as in any aspect of business, there are complications to that formula. If a retailer buys more of an item than customers want, it might have to mark down that item in order to unload it. The more that happens, the farther the retailer gets from its monetary goals.

Couple that with an uncertain economic time for customers, and it can be even more difficult for retailers to forecast what they need to buy. That’s where data and analytics come in. Here’s how companies can use the numbers to make the right call when it comes to inventory.

Importance of a nimble supply chain

The pandemic made a lot of companies much more aware of their supply chains from top to bottom, but it isn’t the only type of disruption that organizations have to take into account. From labor availability to sustainability issues to Mother Nature, there are many factors that could force a company to have to pivot its operations. Supply chain flexibility can benefit the company in two ways – both in getting a product where it needs to be, and in unloading a product as well.

If an unexpected winter storm hits a warm weather area, for example, a chain that sells winter weather clothing could quickly move product to that area if it has the right infrastructure in place. That same flexibility could help the company bypass issues the storm creates when it comes to shipping those items. Similarly, the easier a company makes it for a customer to return an item, the easier it is for the company to re-sell it. If it can create a simple pathway for the customer, the company will benefit. Rather than having the product sitting at the customer’s home until it’s convenient to bring it back, and possibly going out of style, it can be back on store shelves immediately, before it has to be marked down or becomes irrelevant.

How a retailer can go wrong

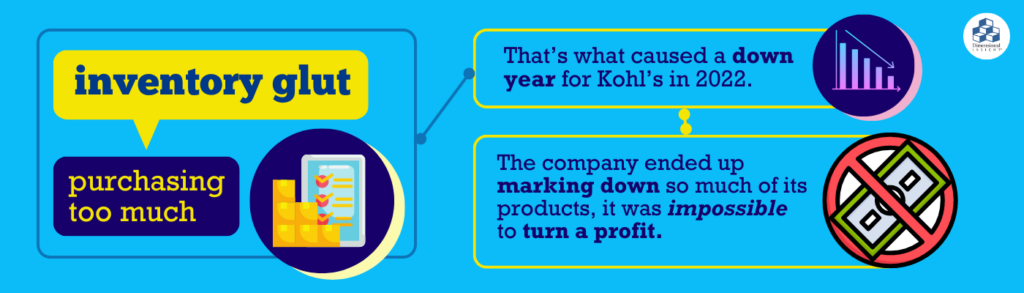

Returns can contribute to the type of problem that can plague a retailer: too much inventory. An inventory glut can also result from purchasing too much. That’s what caused a down year for Kohl’s in 2022. The company ended up marking down so much of its products at the end of the year that it was impossible to turn a profit.

The plan for Kohl’s in 2023 is to cut down on inventory. One way the company plans on doing this is to only add inventory when needed to meet customer demand. It will also more closely monitor slow-moving items, and introduce markdowns more evenly throughout the year rather than waiting until the ends of seasons. These are the types of insights data can provide that can help an organization make decisions.

What Macy’s got right

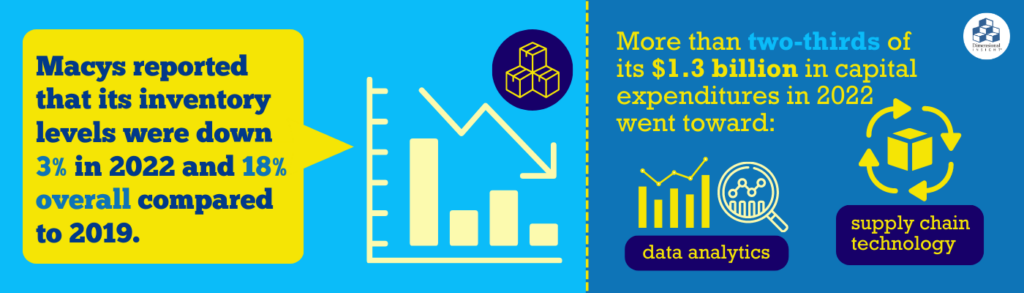

Macy’s is an example of a company that is increasingly using data and analytics to make these types of decisions in a proactive way, rather than as a reaction to bad news. In fact, in an earnings call in early March, the company reported that its inventory levels were down 3% in 2022 and 18% overall compared to 2019. Macy’s executives also said that more than two-thirds of its $1.3 billion in capital expenditures in 2022 went toward data analytics and other supply chain modernization projects, as employees have used data and analytics more to calculate pricing and to forecast sales demand.

Macy’s initiatives covered many aspects of the supply chain, including getting the product to customers. It considered pick-up in store, faster delivery to customers’ homes, package consolidation, so one order doesn’t result in many packages if customers order online, and the company even looked at creating efficiencies in the return process.

Another metric that the company watches closely is related to its customers’ buying: how often they use credit, how quickly they repay, and what debt levels look like. If, based on that information, it looks like the economy is slumping, Macy’s won’t expect as many sales as other years. Macy’s has been credited with a ‘disciplined’ approach to inventory, and it is a model that other companies are likely to try to follow based on its success.

It’s also an approach that is not limited to retailers. Companies across all types of industries are looking at these types of efficiencies, especially since March of 2020. From just-in-time manufacturing to finding enough warehouse storage if they decide to stock up on product, having the right analytics solution in place can help an organization make the right decisions based on its individual situation and needs.

- Summer is an Opportunity for Digital Transformation in Education - April 17, 2024

- Your Car is Tracking More than Miles per Hour - April 11, 2024

- Data Can Help Provide Equal Footing in Cannabis Space - April 3, 2024