In order to function smoothly, the supply chain relies on every part of the process to work without interruption. When ports back up, ships can’t unload goods, which delays the next step in the shipping process. The more ships there are to unload at one port, the harder it becomes for trucks to keep up, and so on in a cycle that is hard to stop. Can data prevent these types of problems? The state of California is trying to find out.

In July, California’s Governor’s Office of Business and Economic Development (GO-Biz) awarded grants that marked the first time in the United States state-level funding was entirely focused on improving data functionality across a statewide network of ports.

The state’s containerized ports handle 40% of all U.S. containerized imports. The $27 million will be used to support data system development and interoperability across the Ports of Los Angeles, Long Beach, Oakland, San Diego, and Hueneme. The awards will fund ten projects across the five ports that will not only bring economic, environmental, and transportation benefits to California, but emphasize what data can do to help improve supply chain infrastructure.

Port Data Partnership

The five ports mentioned above formed the California Port Data Partnership in 2023. The partnership is working to support improved freight system resilience, goods movement efficiency, emissions reductions, and economic competitiveness.

The hope is that the work being done in California will provide a model that can be replicated across the country, leading to improved collaboration around data elsewhere, and helping improve efficiencies across the supply chain. For the larger ports with data systems in place, the data sharing allows for attempts at more ambitious projects. For the smaller ports involved, this is a chance to use data in a more meaningful way than their resources might have allowed them to do before.

Benefits

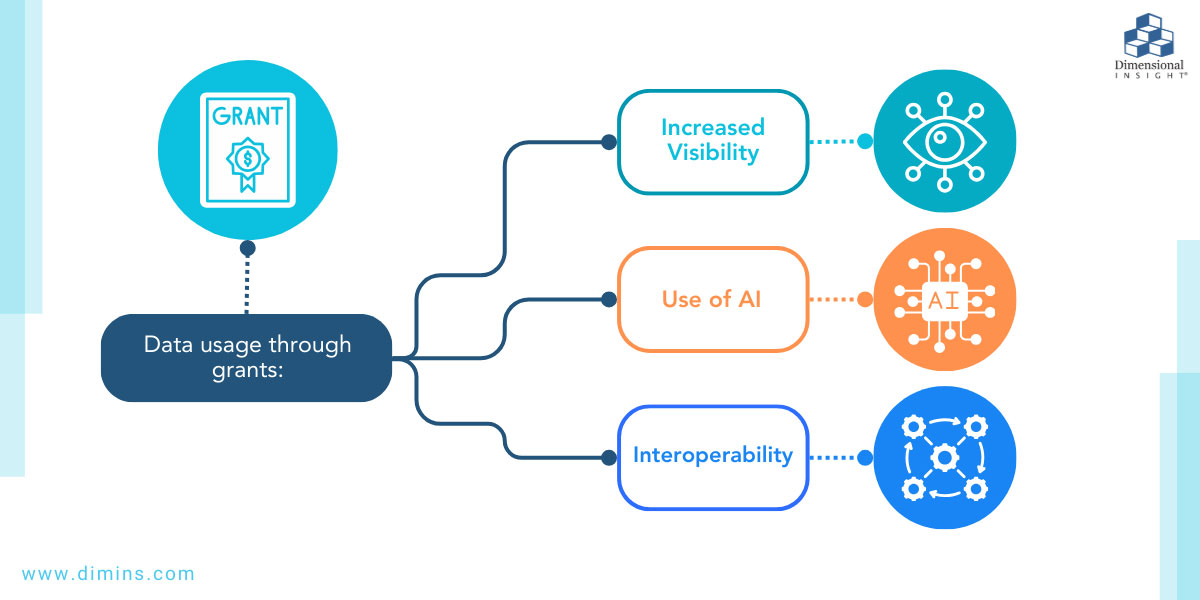

The projects being funded will use data to help with everything from meeting federal regulations and climate goals to making sure the ports are operating at peak efficiency. Here are some of the ways the grants involve optimal use of data:

- Increased visibility: At the Port of Los Angeles, data systems allows for up to 40 days of visibility on cargo. This allows organizations to plan and make scheduling and operational decisions before the cargo arrives, leading to more efficient and cost-effective delivery. Much of the information is available on the cloud, allowing easy access that is available everywhere and at all times to whoever needs it.

- Use of artificial intelligence: The Port of Los Angeles is working to use AI to improve the way truckers make appointments, using real-time container tracking and cross-terminal scheduling. At the Port of Long Beach, one project involves using technology that can read container numbers from passing trains. Like other uses of AI, the technology is being used to capture more information more quickly than people can do on their own.

- Interoperability: Much of the data will be integrated from port to port, not just along the California coast, but also with foreign organizations. There is also the ability to connect to the Department of Transportation’s Freight Logistics Operations Works (FLOW) program, which allows supply chain industry stakeholders to share real-time data.

Though California’s ports have had parts of these projects in the works for years, a lot of the impetus for the recent work was the supply chain disruptions that came about as a result of the pandemic. The lessons learned from those delayed shipment arrivals and then the ensuing backups at the ports have led to some of these solutions in order to prevent similar issues the next time there is a major disruption.

So much of the work being done with data is true of analytics in any industry. When many stakeholders are involved, different data sets can not be siloed. Communication is key, and the more the data can be shared between stakeholders, the better that data can be put to work for everyone. In this case, whether it is solely California’s ports or the wider data-sharing community involved in FLOW, these improvements are likely to have a wider impact on the supply chain industry.

The same kinds of technology being used to achieve these goals in California may not be available to all organizations looking to improve these aspects of their supply chains. But part of the goal is to share the data they are collecting to improve the supply chain overall. The best analytics solutions can take that data and integrate it with any data system, allowing you to reap the benefits of data you might not be able to gather on your own.

- The Latest Fashion Trend? Analytics in the Apparel Industry - April 1, 2025

- How Analytics Provides Stability During Volatility in Beverage Alcohol - March 25, 2025

- Analytics Are a Key to Handling Increased Tariffs - March 20, 2025