Organizations rely on transparency in their supply chains for any number of reasons. Following the pandemic, companies that did not have their supply chain entirely mapped out came to see the practice’s importance. Instead of finding out about supply chain weaknesses when something stopped working, they could identify and address potential problems ahead of a disruption.

Organizations have taken new approaches recently to help track the origins of their products, and they’ve begun using technology that is new to the industry in order to do so. Here’s why supply chain transparency is important, and how technology is helping organizations be more aware of their goods at every step of their production process.

All eyes on supply chains

Supply chain transparency certainly matters to the organizations selling a product, but it is also important to consumers. Many customers demand a level of ethical practice by the companies to which they give their business, and they want to know that there has not been any illegal aspect in the production process.

Another result of the pandemic is that consumers became much more aware of the existence of supply chains. The lack of certain products in supermarkets was one eye-opener. Customers suddenly became more aware of what might prevent a paper product from reaching store shelves or what technology relied on a certain computer chip that was unavailable due to a factory shutdown on the other side of the world. But people also have become accustomed to tracking their purchases from their point of origin all the way through the moment it shows up on their doorstep.

DNA tracking

As the demand for supply chain transparency has grown, organizations have adjusted accordingly. One strategy for companies that want to make sure they are using appropriately sourced materials is DNA tracking. Not too long ago, retailers sold bedsheets that were said to have been made from “Egyptian cotton.” It turned out the cotton was not from Egypt, and the companies faced expensive recalls and lawsuits.

DNA tracking allows organizations to avoid facing a situation where materials are produced somewhere other than what they expect. A company called Applied DNA Sciences can spray a DNA mist onto freshly cleaned cotton in California before it is shipped to factories in India to be turned into yarn that is used to make bedsheets. By testing the end product’s DNA, the retailer can be sure that the American-grown cotton hasn’t been replaced by a cheaper material from elsewhere.

That leads to the environmental, social, and governance (ESG) elements of this kind of transparency as well. Some companies need to keep a close eye on their supply chains because they face punishments if there is a mistake. If cotton that a company thinks is American-grown, for example, turns out to have been switched with cheaper cotton from the Xinjiang region of China, those goods could be detained. Xinjiang’s ties to forced labor have led to products from the region being banned in the United States.

Advanced technology helping with transparency

Artificial intelligence (AI) can be used to uncover similar problems. AI is used across different industries for its ability to scan large numbers of records at high speeds. In this case, it can identify potential fraud or search supply chain networks for links to possible banned suppliers, tasks that involve billions of records that would take years to accomplish if humans were doing the work unassisted.

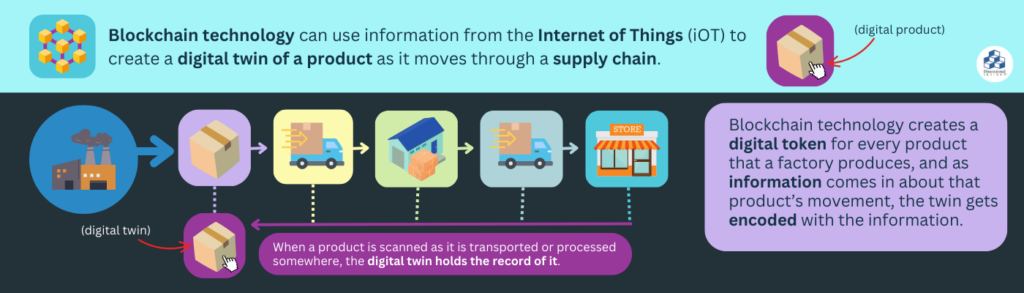

DNA tracking isn’t the only way organizations can get a full picture of where material comes from and where it has been. Blockchain technology can use information from the Internet of Things (iOT) to create a digital twin of a product as it moves through a supply chain. Blockchain technology creates a digital token for every product that a factory produces, and as information comes in about that product’s movement, the twin gets encoded with the information. So when a product is scanned as it is transported or processed somewhere, the digital twin holds the record of it.

It many cases it can be difficult, if not impossible, to fully trace a supply chain. A large, multinational company like Proctor & Gamble could have tens of thousands of suppliers, which each might rely on hundreds of other sources for the parts that make up a final product. Those sources might rely on multiple other organizations, and so it continues down the line.

The effort might be worth it, though. Recent research suggests organizations that focus on ethics, environmental, and labor practices within their supply chains are more profitable than those that don’t. Whether it’s investing in a business intelligence solution to help maximize a supply chain’s efficiency or creating a full digital twin of the chain from top to bottom, being able to create the most transparent supply chain possible is likely to produce more positive results than negative for an organization.

- Summer is an Opportunity for Digital Transformation in Education - April 17, 2024

- Your Car is Tracking More than Miles per Hour - April 11, 2024

- Data Can Help Provide Equal Footing in Cannabis Space - April 3, 2024